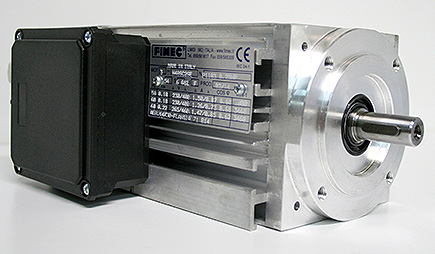

COMPACT SAW MOTORS- GENERAL FEATURES

synchronous three-phase and single-phase motors with compact dimensions have been studied for all those applications in which an high output but limited dimensions are requested. They are suitable for applications on cutting machines (e.g. circular saws) because the lowered shape allows the maximum exploitation of cutting height. They are particularly suitable for all those machines and applications where the required motor space has to be reduced as that of standard round motors.

Saw motors are usually supplied with a left or right hand threaded shaft, two flanges and one nut for the fastening of cutting tool. Shaft can be easily modified according to our customers’ needs.

Compact saw motors can be employed with an inverter (more information on chapter 3.5).

Three-Phase and single-phase saw motors can be supplied with d.c. safety brake or with Fimec patented pneumatic brake. These two types of brake are particularly suitable for cutting machines safety stops, as parking brake, etc. featuring: motor overall dimensions keeps unchanged compared to the design without brake, high braking capacity.

Features of Fimec compact saw motors are:

STANDARD SUPPLY: Saw motors are usually supplied with standard European tension 230/400V. ±10% or 400/695V. ±10% at 50hz and standard American tensions 230/460V. 60hz. . Dc brake can be wound at 230Volt (±10% )or 400Volt ( ±10%) Motors and brake can be easily supplied with other tensions on request for working in countries all over the world. It is also possible to supply motors wound at 100hz. Max. brake and rectifier tension is 440V. ±10% . If you think your brake tension may exceed 440V +10% (this might happen in some American or English countries), we can supply, on request, a special rectifier connected at the brake.

HOUSING: made of extruded light alloy. Flat casing, finned on three sides and feet obtained from equal longitudinal tee slots on overall length.

FLANGE: saw motors are supplied with a drive-end shield and non-drive end shield. On request, without addition in price, drive end shield can be supplied with holes as It were a B14 flange.

TERMINAL BLOCKS: with 6 terminals (on request 9 or 12) for motor supply. Dc brake can be fed directly from motor terminal block or separately. Earth terminal located inside the terminal box.

TERMINAL BOX: metallic or thermoplastic terminal box usually positioned on the right side of the motor (near the exit shaft, as shown in the picture). On request, It can be positioned on the right side near the fan cover or on the left side (near the exit shaft or the fan cover) and also on the top of the motor or on the bottom of the motor. The terminal box can also be rotated in steps of 90° in order to provide cable entry from different directions. Every motors are provided with a terminal for grounding.

CABLE GLANDS: are pull-out resistant V-TEC cable glands. Made of a specific plastic and certified according to UL directives and other European standards.

FAN: saw motors are fitted with bi-directional radial fans keyed externally onto the non-drive-end shaft. Made of thermoplastic material strengthened with fiberglass or made of aluminum when motors mount the brake.

ADDITIONAL VENTILATION : In case saw motors are employed with Inverter at very low speeds, we suggest to request the application of an additional ventilation, fed separately, i.e. obtained by means of an axial flow servo-fan whose air flow rate is independent from motor speed. Use of the servo-fan is recommended for motor speeds lower than the nominal speed (usually under 40hz), when the air flow rate of the standard fan would be insufficient for correct cooling.

FANCOVER: made of thermoplastic material up to frame 90 and of aluminum for size 100.

ROTOR: die cast cage aluminum rotor . Rotors are balanced with half key inserted into shaft extension.

PROTECTION: standard protection is IP54 . On request we can supply saw motors with higher protection by using specific seals (IP55) or by creating a special labyrinth in the front shield for protecting motors employed in aggressive situations (for example, when water sprays reach the motor) . It is also possible to employ a specific red paste which seals the motors almost hermetically and protects it from possible water jets.

MOTOR WINDING: manufactured with class H copper conductor insulation, double coat insulated, type of impregnation with class H resin; other materials are usually class F and H protected. Components are all UL certified. On request, It is possible to insert in windings three termistors wired in series for connection to a suitable contact breaker device .

SHAFT: in standard execution, saw motors are supplied with a left or right hand thread. Usually made of C43 steel. On request, wide range of non-standard designs are available for every needs.

BEARINGS: high quality radial bearings are employed.

SINGLE–PHASE MOTORS: Single-phase saw motors are equipped with a run capacitor permanently turned on and connected to the auxiliary winding for starting. Single phase saw motors type SEM are suitable for being used in those machines that start without charge. Single-phase motors can be also equipped with d.c. security brake or pneumatic brake.

CONNECTION TO AN INVERTER: Saw motors can be employed with inverter (reference chapter 4.5)

(Download data sheet)

(Download spec)